You don’t need to juggle disconnected products to manage your manufacturing quality.

While at IMTS, don't miss how you can implement Quality 4.0 and consolidate your quality tools into a single integrated solution.

The experts from High QA can show you how to consolidate your quality management tools into a single, all-in-one integrated solution for manufacturing quality that saves you time and increases productivity.

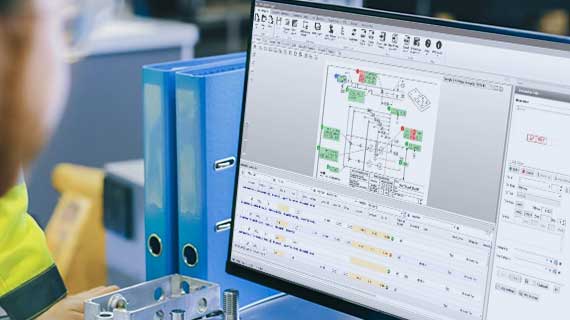

High QA helps you unite engineering, production and inspection teams with an all-in-one manufacturing quality software solution to streamline ballooning, planning, production, reporting and submissions.

You don’t want to miss this opportunity. Visit High QA in booth #135348.

Putting Quality 4.0 into action has never been easier.

1

Click to Balloon Drawings and Extract GD&T/PMI Data

5x

Productivity Improvement for Existing Personnel

75%

Faster Generation of PPAP Documents and Requirements

Your All-in-One, Get-It-Done Software for Manufacturing Quality

Reduce costs, improve quality, streamline processes, and maintain compliance internally and across your entire supply chain

Can't see us at IMTS? Request a demo of High QA software today! Request a Demo

High QA software enabled JD Machine to have scalable growth while maintaining cost, quality, and delivery

JD Machine needed to keep overhead low and spend less time checking parts while increasing part quality and efficiency.’ .

The search began for a system that could manage their manual inspection data collection as well as meet requirements of customer contracts, PPAP documentation, SPC, internal inspections, etc.

Their search ended with High QA software. It was the only solution that allowed JD Machine to scale from small beginnings to big growth and accommodate highly complex projects all while ensuring a high level of quality.

Experience the High QA Difference

One of the most critical aspects of a manufacturing operation is quality management. Whether you are struggling with quality processes like ballooning/bubbling prints, FAI, or PPAP, or dealing with parts trending out of specification, or a lack of end-to-end part visibility and tracking, High QA manufacturing quality management software enables your manufacturing company to plan, manage, document and control your manufacturing and supply chain quality needs.

It’s time for you to reduce mistakes and be more efficient. High QA organizes and automates all aspects of a first article inspection report to reduce the cost and time involved – and prevents errors along the way – helping you streamline your manufacturing process. And that leads to improved quality products, increased customer satisfaction and a successful business.