Spotlight on Aerospace & Defense Manufacturing Quality

Integration of Production Part Approval Process (PPAP) with Manufacturing Quality Management Data Threads Throughout the Supply Chain Can Help to Avoid Delays and Rejections in Aerospace, Automotive & Other Industries by Helping Manufacturers Document, Control, and Predict Better Quality

High QA

We all read the same news: In the aerospace sector, where a quality-related defect in a small part such as a bolt can have huge consequences. Because of the aerospace industry’s high visibility, the degree to which a manufactured part or component or assembly (“parts”) matches specifications has, for a host of reasons we will not delve into here, received greater attention from safety inspectors, the general public, and the news media than similar occurrences in other industries. Instead, we will explore some of the root causes behind those quality-related deficiencies and suggest some ways to address them.

Although instances in which parts do not meet quality standards appear to be rare occurrences, with global demand surges and the heavy potential cost of flight delays and accidents, manufacturers must address these hurdles to ensure quality and reliability.

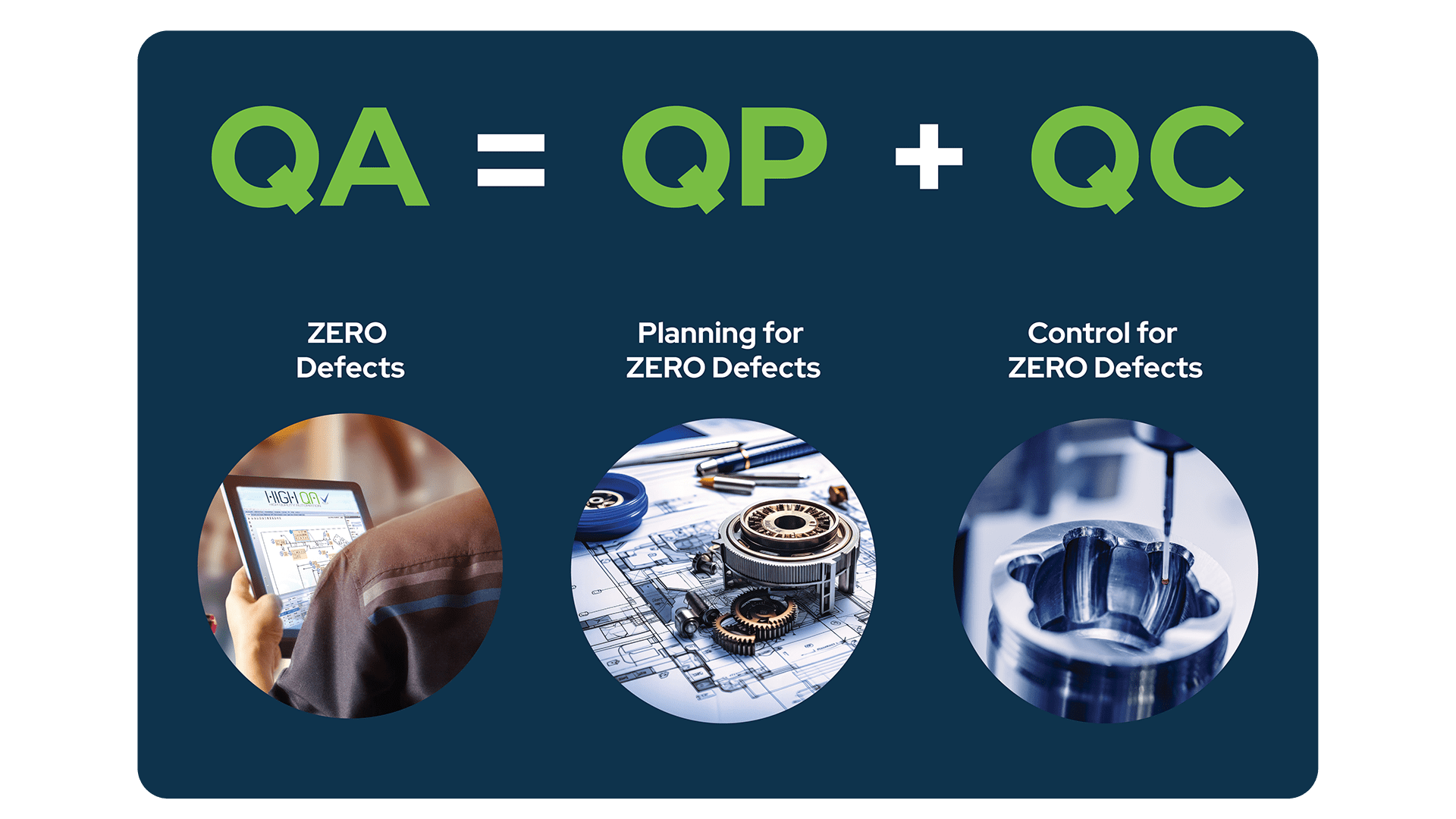

Specifically, it is possible to improve upon the status quo by integrating Quality Assurance (QA), Quality Planning (QP), and Quality Control (QC) into a seamless and symbiotic approach.

Think of Quality as a formula for success:

To make certain one clearly understands the definitions of QA, QP, and QC in this context;

QA relates to how a process is performed or how a part is made to ensure zero defects,

QP is the process of planning all the procedures that are necessary to ensure product quality before the part is made, and

QC is the process of measuring and documenting manufacturing quality when the part is made.

Looking back at our numerous customers in the Aerospace sector, through better multi-function collaboration and data integration, our experience has been that the creation, management, support, and monitoring of aerospace manufacturing quality processes can take only ¼ of the time compared to using traditional, semi-manual methods, and offer a significant reduction in scrap, defects, and potential escapes.

Because of the way the supply chain works, aircraft or system designers (OEMs) turn to suppliers in the industry through a system of tiers. This is where the challenge begins. Through a system of “pass-throughs,” buyers share information about the part and its specifications down to suppliers through “packages” of work that are being “interpreted” by manufacturers to make parts. Most of the time, all works well: Parts are made, shipped, and inspected without a hiccup. Other times, QP does not talk to QC and vice-versa.

From this simple observation, the failure to integrate QA, QP, and QC may have led to recent quality-related issues in the aerospace industry.

In a recent incident, a company said it “couldn’t find the documents” regarding an investigation related to improper bolting of an exit door. The defect led to an in-flight incident shortly after takeoff in which the door separated from the fuselage, forcing the aircraft to return to its originating airport.

Other occurrences of quality breakdowns include a specific model of aircraft being grounded due to problems with automatic flight control features, deliveries of a widebody aircraft being delayed by more than a year due to defects in the fuselage, aircraft built using the wrong blueprints and improperly inspected parts, improper installation of brackets to join an aircraft’s fuselage to the tail fin delaying delivery, improperly drilled holes on a bulkhead, a bolt on a rudder control system missing a nut, and trash and empty tequila bottles left inside aircraft built for, and delivered to, government customers.

Thrust for Change Can Create Lift

Some of these incidents may have multiple root causes beyond manufacturing quality, but one thing seems clear: The aerospace industry’s manufacturing quality-related challenges could be improved with the right systems in place.

For that reason, digital transformation is needed to unlock growth and efficiency and prevent manufacturing quality issues from occurring.

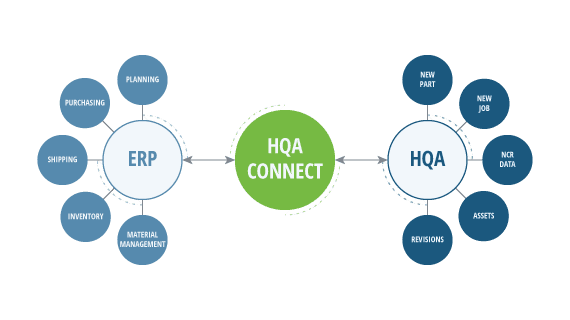

The solution should include well-connected (integrated) manufacturing quality processes. If manufacturers throughout the supply chain cannot collaborate without interpretation of what QA, QP and QC mean in a collaborative, seamless data exchange from a single source or database, “escapes” will continue to happen, lives will continue to be lost, and individuals’ careers and companies’ reputations will continue to suffer.

In many, if not most instances, aerospace companies are using semi-manual or badly integrated systems that rely on multiple databases instead of a single database — a single source of truth — and are prone to misinterpretation and human error.

Reasons for this inaction range from a general lack of awareness about modern data management possibilities, rigid regulations and/or certifications that may inadvertently create a form of paralysis, and in some instances, an investment in technology and systems that is perceived to be beyond the reach of some of the players. That last point is also due to system providers wanting to create closed systems around their products.

This issue needs to be addressed to get to common standards for an open architecture approach that manufacturers can use to collaborate with designers without having to spend tens of thousands of dollars to simply read what they need to know. This deficiency is still a problem when using 3D models. As a result, many suppliers are still relying on 2D prints of yore to make sure things will fit.

A Wide-Body Solution

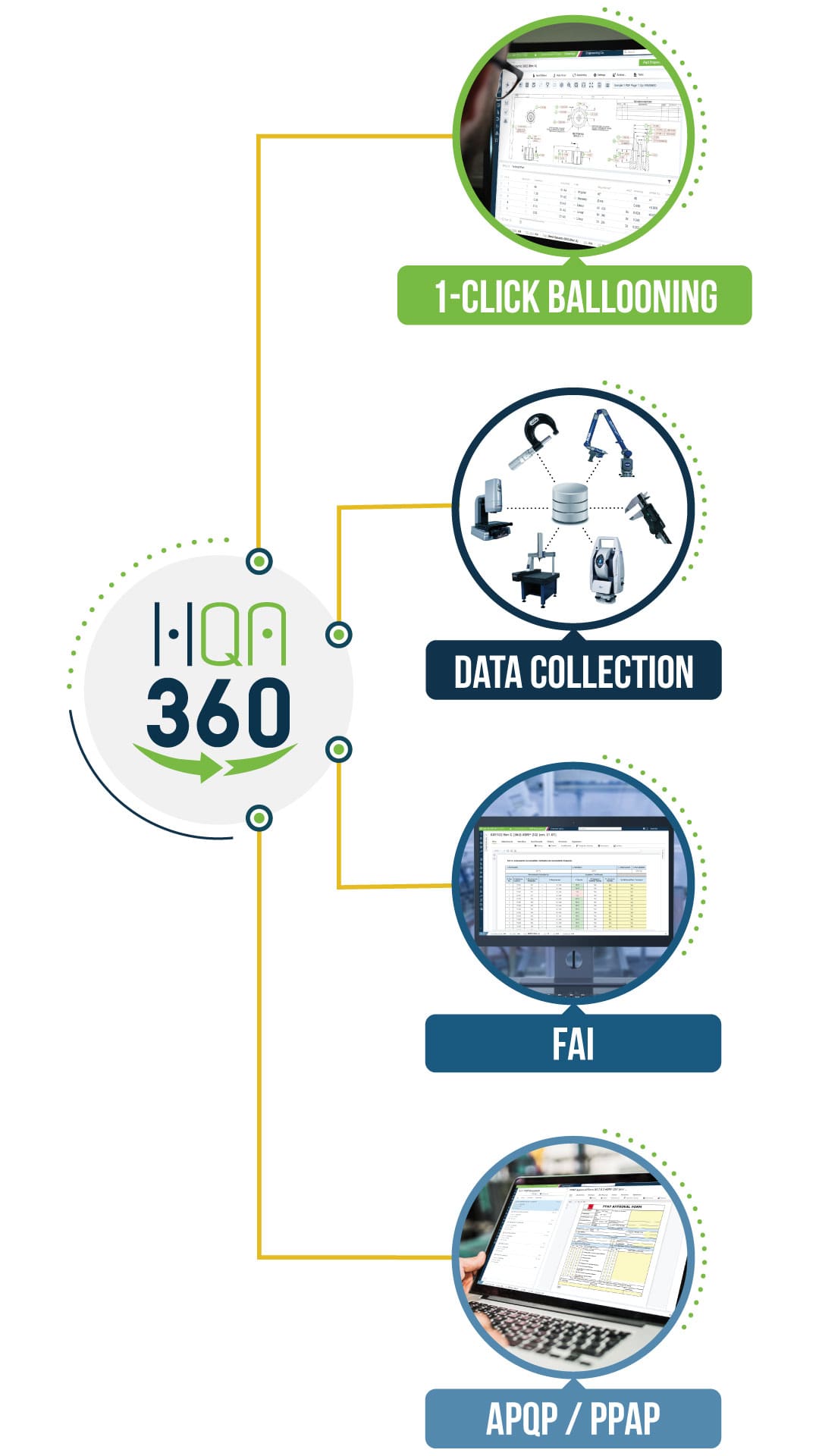

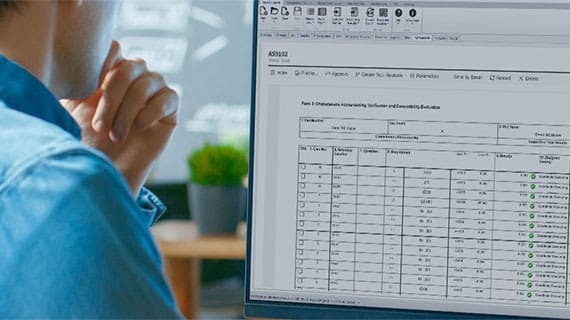

Aircraft manufacturers and their supply chain partners can benefit from using comprehensive, integrated “all-in-one” tools for QP and QC: Ballooning, First Article Inspection (FAI), Gauge Management, Shop Floor Data Collection, Statistical Process Control (SPC), Process Failure Mode and Effects Analysis (PFMEA), Control Plans, and Production Part Approval Process (PPAP).

Doing so would help to reduce costs, prevent human interpretation errors, and improve delivery time and part quality, as well as help manufacturers comply with AS9100, AS9145, and AS13100 standards.

What’s more, FAI Reports (FAIRs) and other kinds of reporting can be generated in minutes instead of hours or days to give everyone concerned full visibility in real time, or near real time, into the quality and delivery times of parts.

If companies make relatively modest investments in consolidating their quality systems and linking them to the systems of their supply chain partners, digitally unifying and templatizing interaction and collaboration, and improving communication and process tuning, there is a high probability that the quality of their products will improve, which can go a long way toward bolstering productivity and profitability.

As history has shown, having the right tools and using them to maximum advantage is just as important in the C suite as it is on the shop floor.