Wed, Jun 3, 2020 11:00 AM – 12:00 PM EDT – Reach 4.0 Quality Goals Through Automation, Collaboration with Trusted Data from 2D/3D Files to FAI

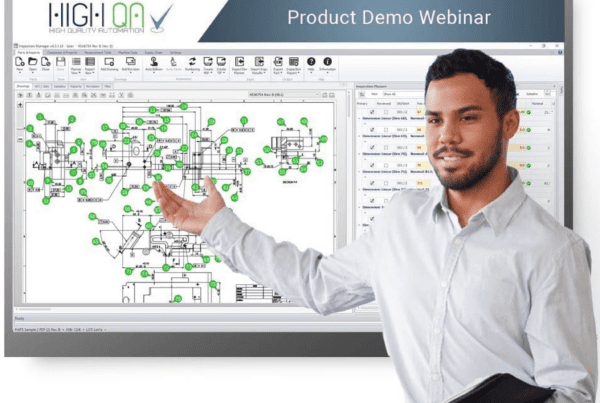

Quality 4.0 is becoming today’s reality. While automation moved to the manufacturing floor last century, automating the basic quality processes lags. A gaping hole exists between CAD\CAM and quality automation. Many manufacturers still use pencils on paper to balloon their drawings and manually collect data for reporting. It takes longer to produce the necessary documentation than manufacture the part. Manual operations result in a higher than acceptable margin of error due to labor-intensive, individual interpretation of drawings, handwritten data and transcription errors when data is entered into a spreadsheet. Errors increase when data is outsourced to suppliers.

Primary Topics:

- How automation helps you meet Quality 4.0 goal

- Value of the starting with the 2D drawing or 3D Model

- Use of a centralized database for trusted data throughout the inspection process

- Manage communication with outside suppliers effectively