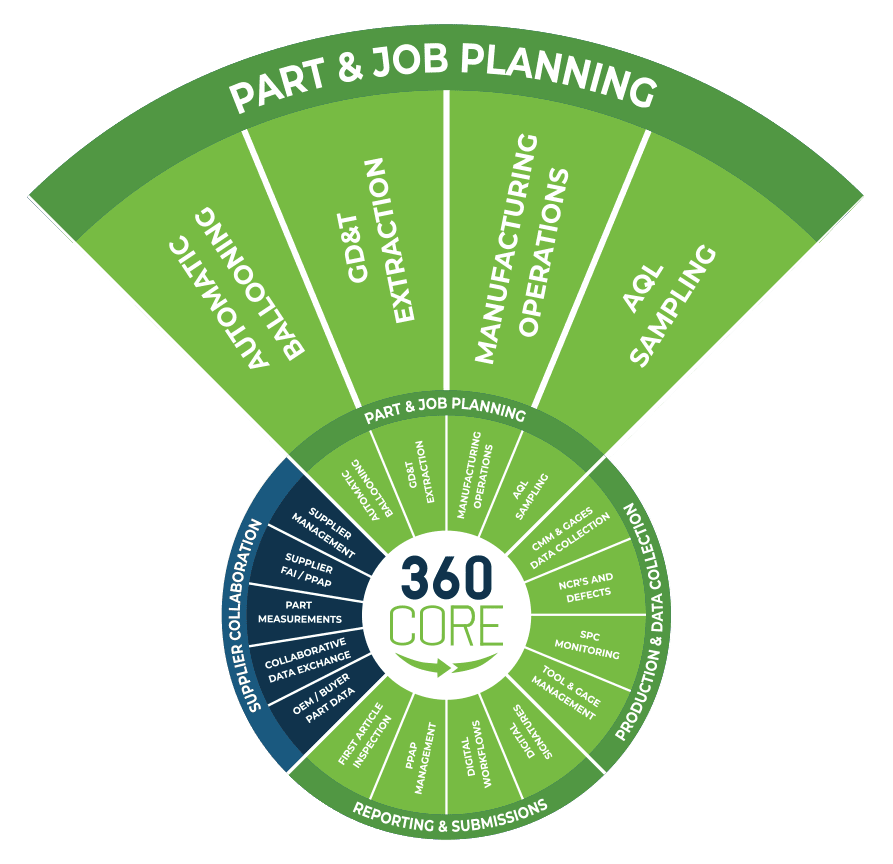

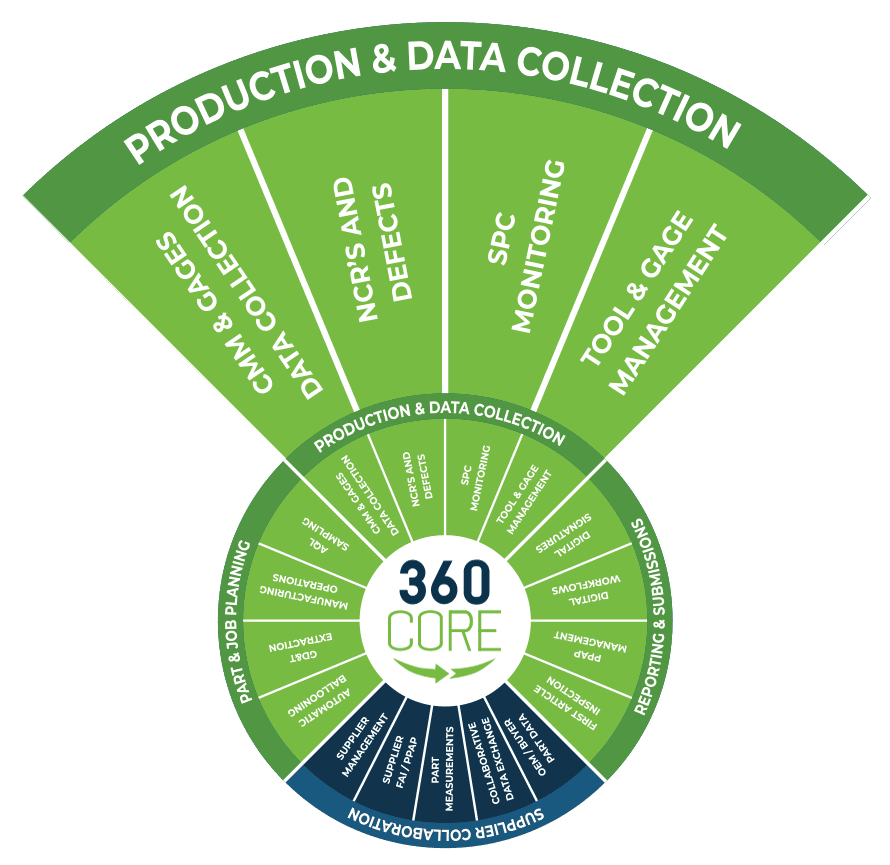

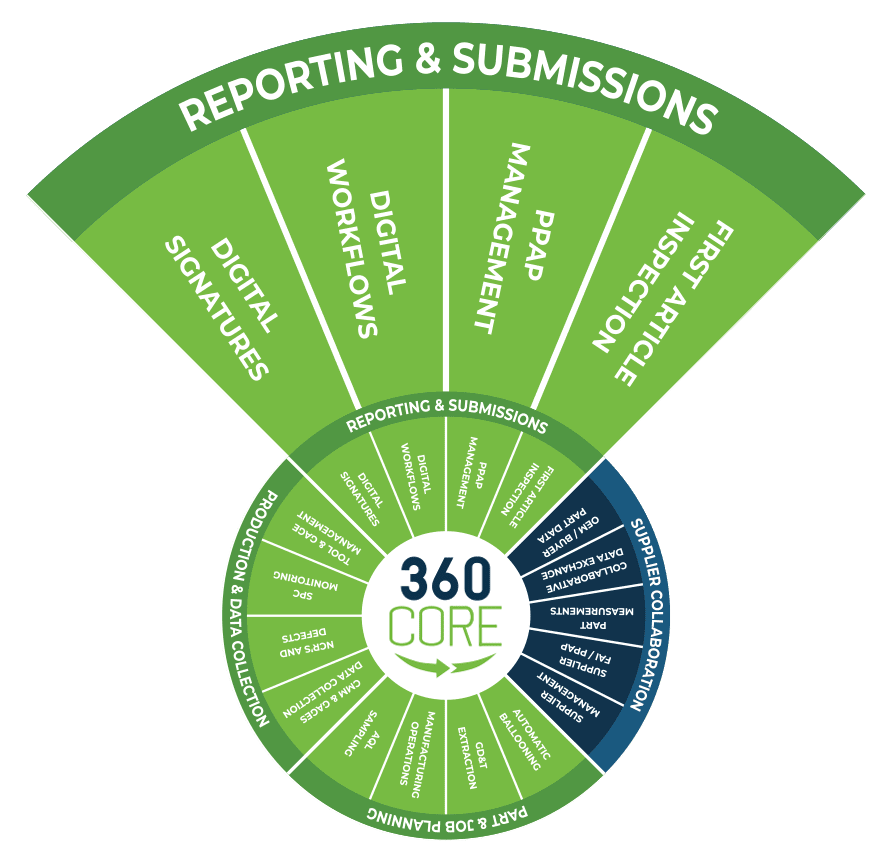

360 CORE, the quality manufacturing software, allows more than 1,300 users worldwide to collaborate with quality data in a single database that can be hosted on premise or on a private, secured cloud server.

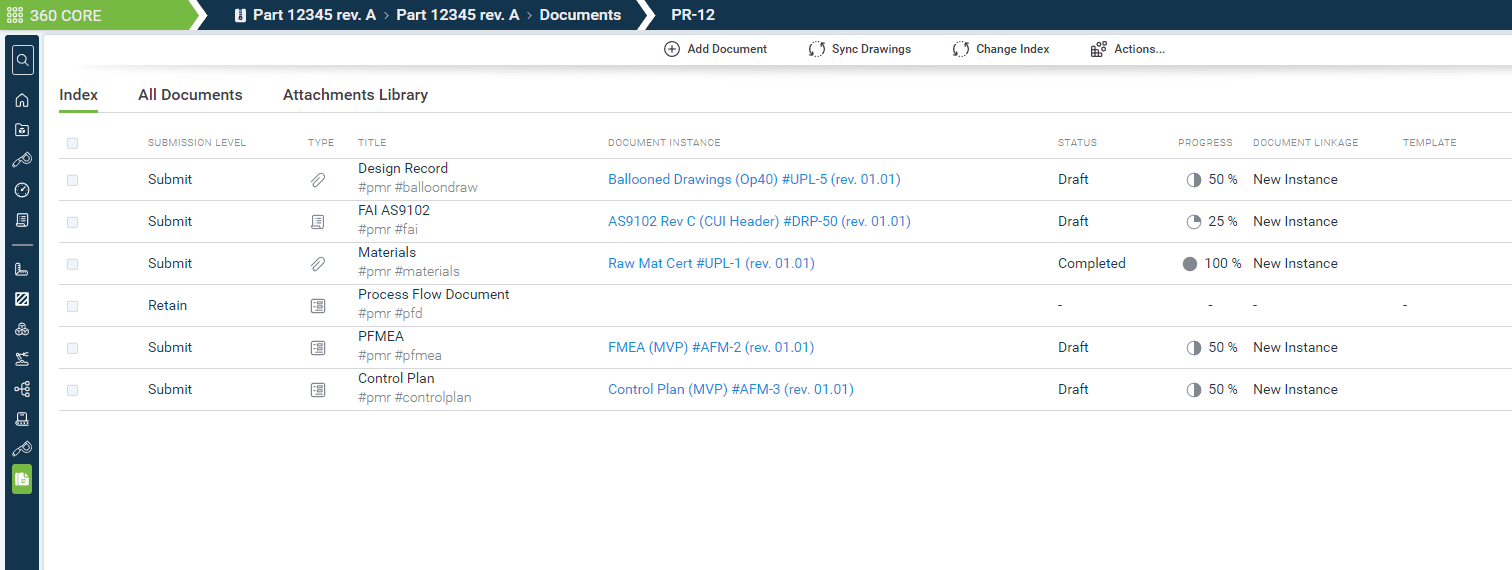

Our unified Quality Management suite helps you win more business by simplifying and automating your manufacturing quality both internally and throughout your supply chain.

What is a Quality Management Suite (QMS)?

A quality management suite (QMS) is aimed at manufacturing quality management inside a facility, division, or enterprise.

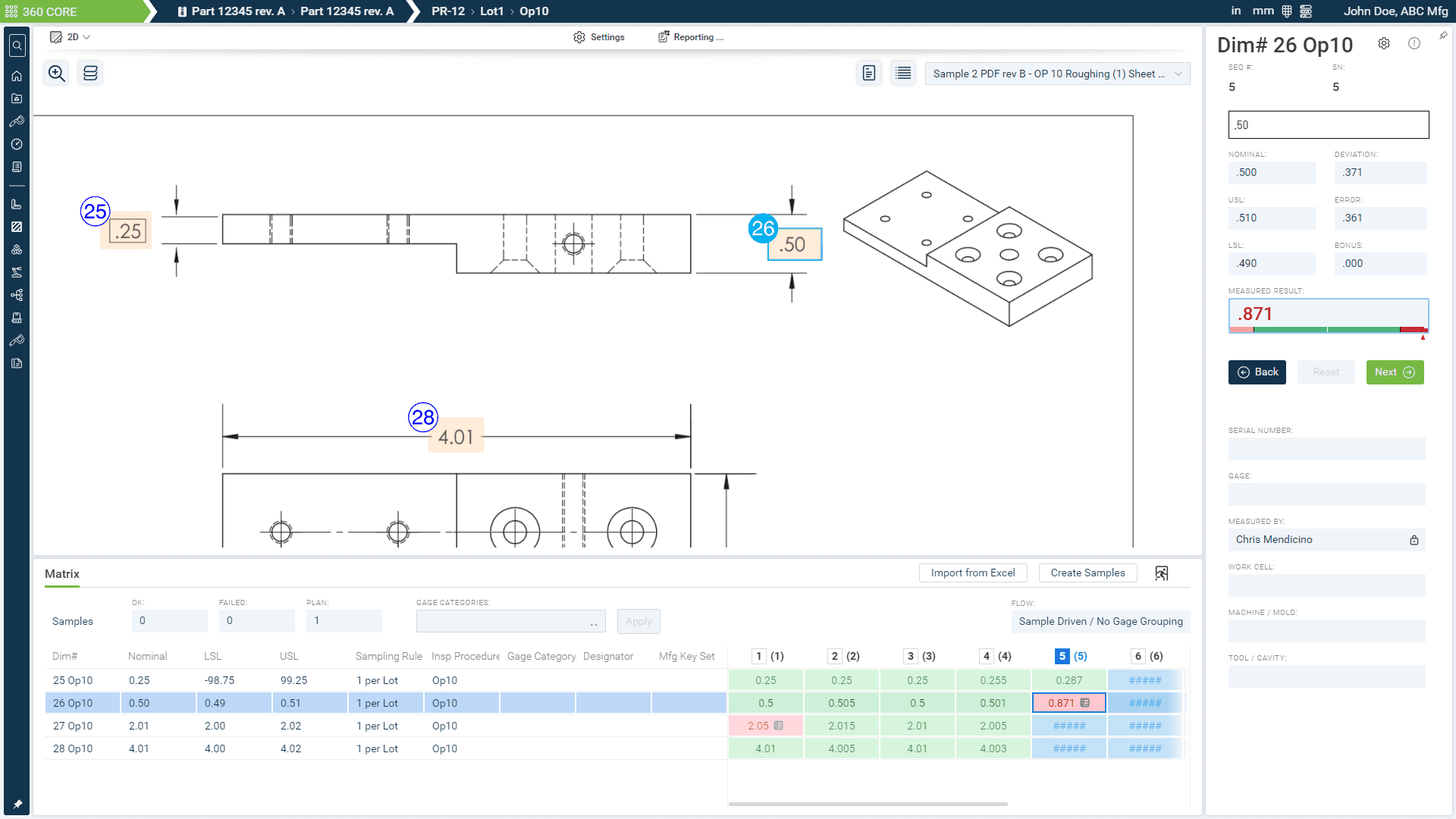

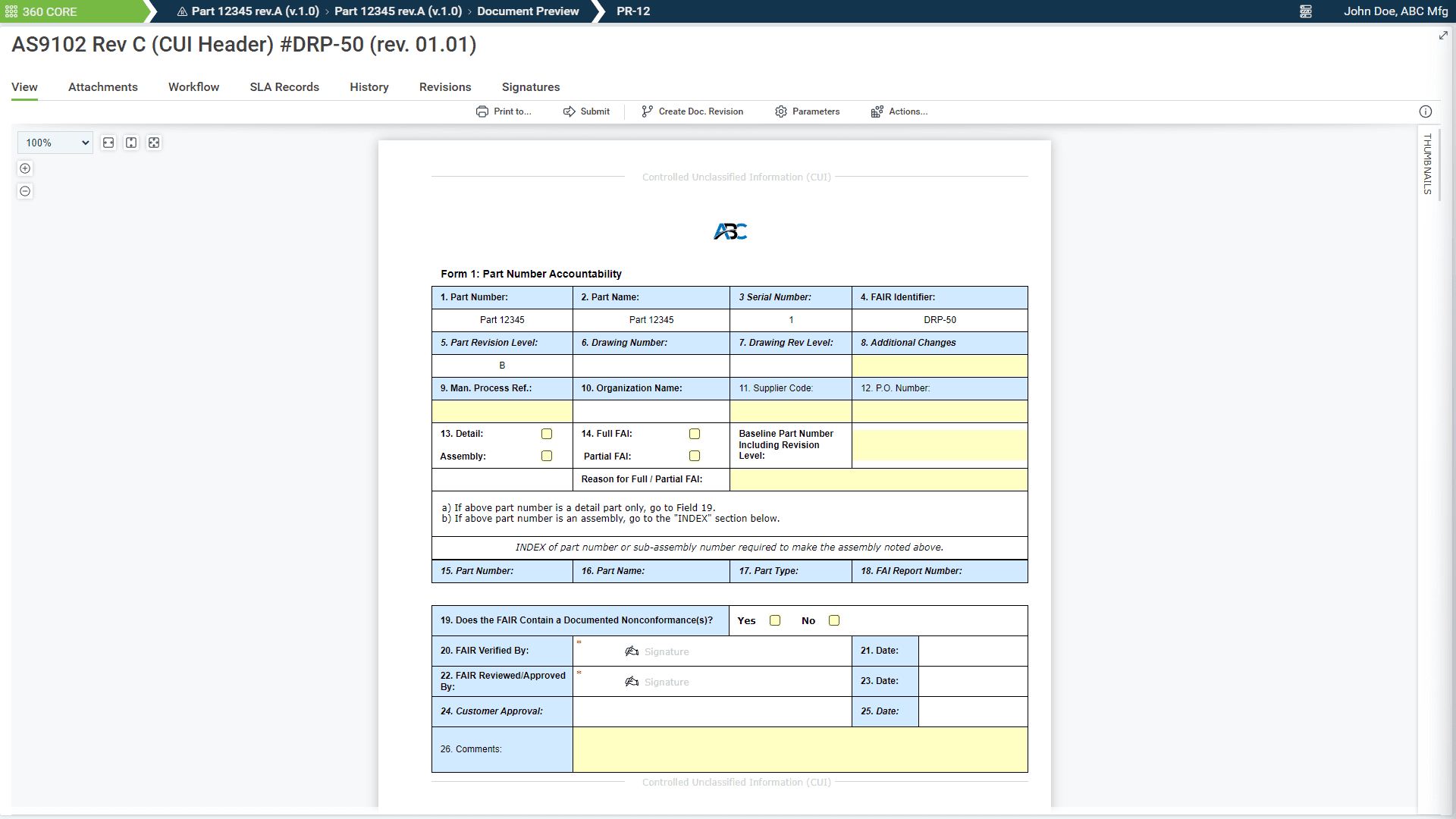

360 CORE is an all in one CMMC Compliant toolset that optimizes your quality planning, inspecting and reporting with intuitive tools that help your teams deliver high quality parts on time, on quality and on budget.

This CMMC compliant toolset is an all in one manufacturing quality suite that optimizes your quality planning, inspecting and reporting with intuitive tools that help your teams deliver high quality parts on time, on quality and on budget.

On the Cloud, is my Data safe?

Fully ITAR and CMMC compliant, we also have built in digital rights management letting you manage which specific users in your network, and among your suppliers, can access specific content.