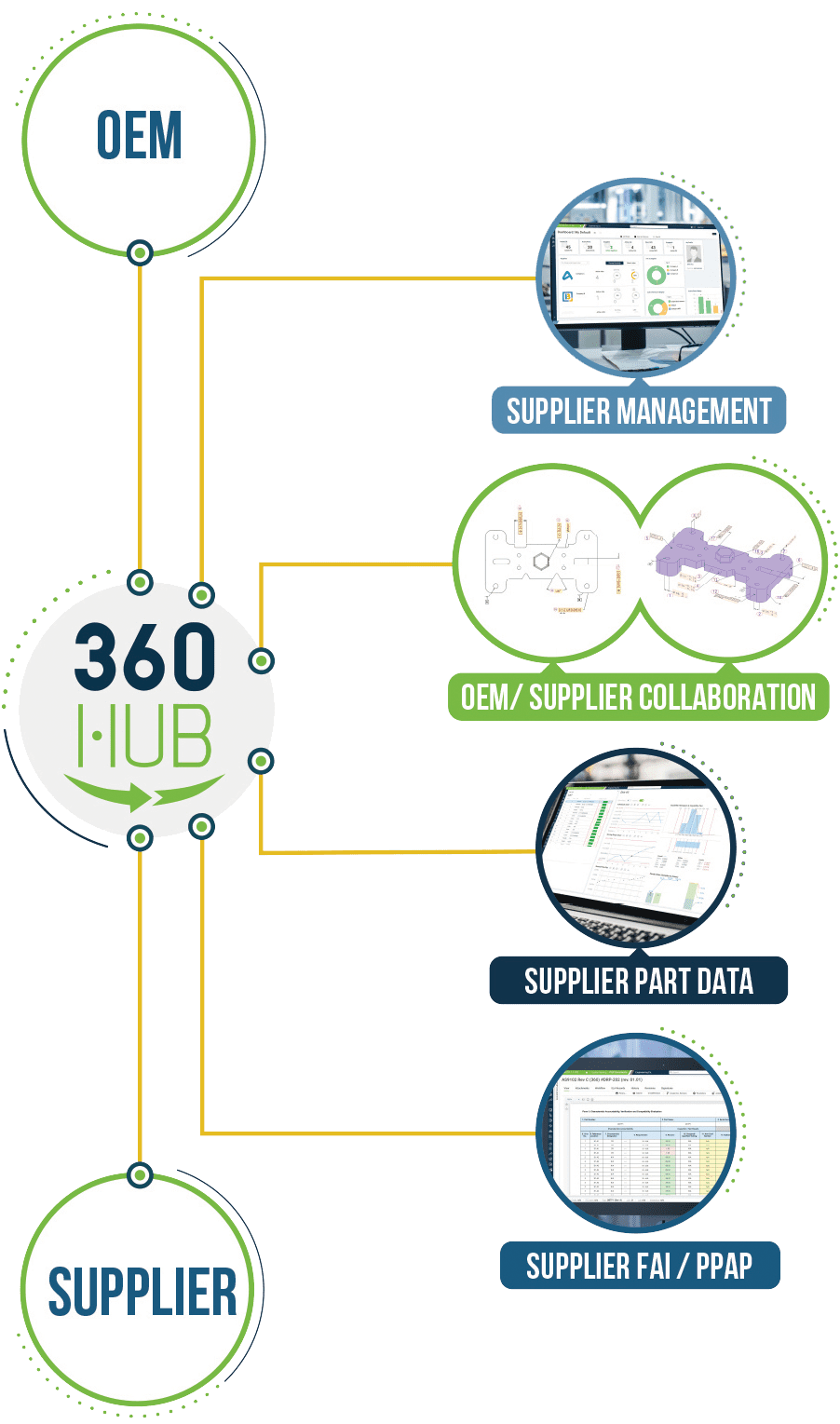

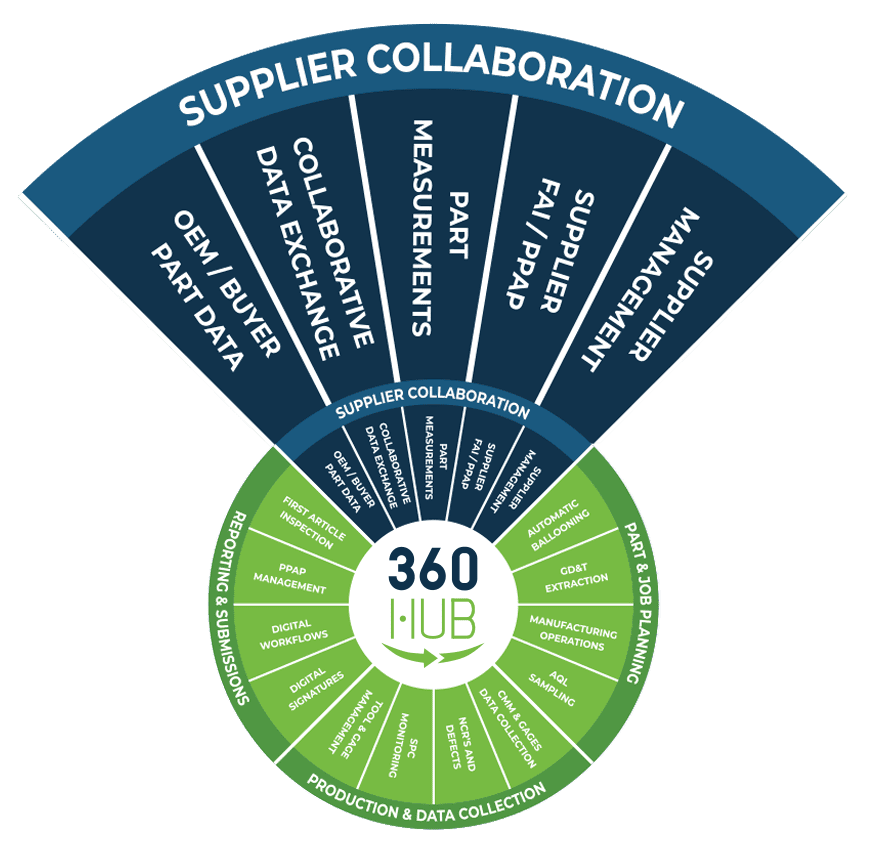

As a user, you invite your supply chain partners to the 360 HUB, making it easier to securely share prints, models, forms, and other documents. 360 HUB allows for standard submissions of RFQs, QA reports, and other critical documentation. Based on data the system collects, HUB enables you to choose the right suppliers, predict deliveries and quality, as well as respond accurately to RFQs.

360 HUB gives you peace of mind that you’re getting parts or components that meet your quality requirements because your supply chain partners have all the information they need to give you an accurate quote and manufacture to specification exactly what you need, on-time and on-budget.

Because 360 HUB gives your supply chain partners access to complete information, it decreases the probability of failures occurring up and down the chain.

- Buyers invite Suppliers to the 360 HUB.

- 360 HUB allows the secure exchange and sharing of prints, models, forms…

- 360 HUB allows for standardization of submissions through the supply chain from RFQ to QA report.

- 360 HUB allows to learn with data over time to pick the right supplier, predict deliveries and quality, or respond accurately to RFQ’s

- 360 HUB allows productivity and collaboration with less friction within the supply chain.

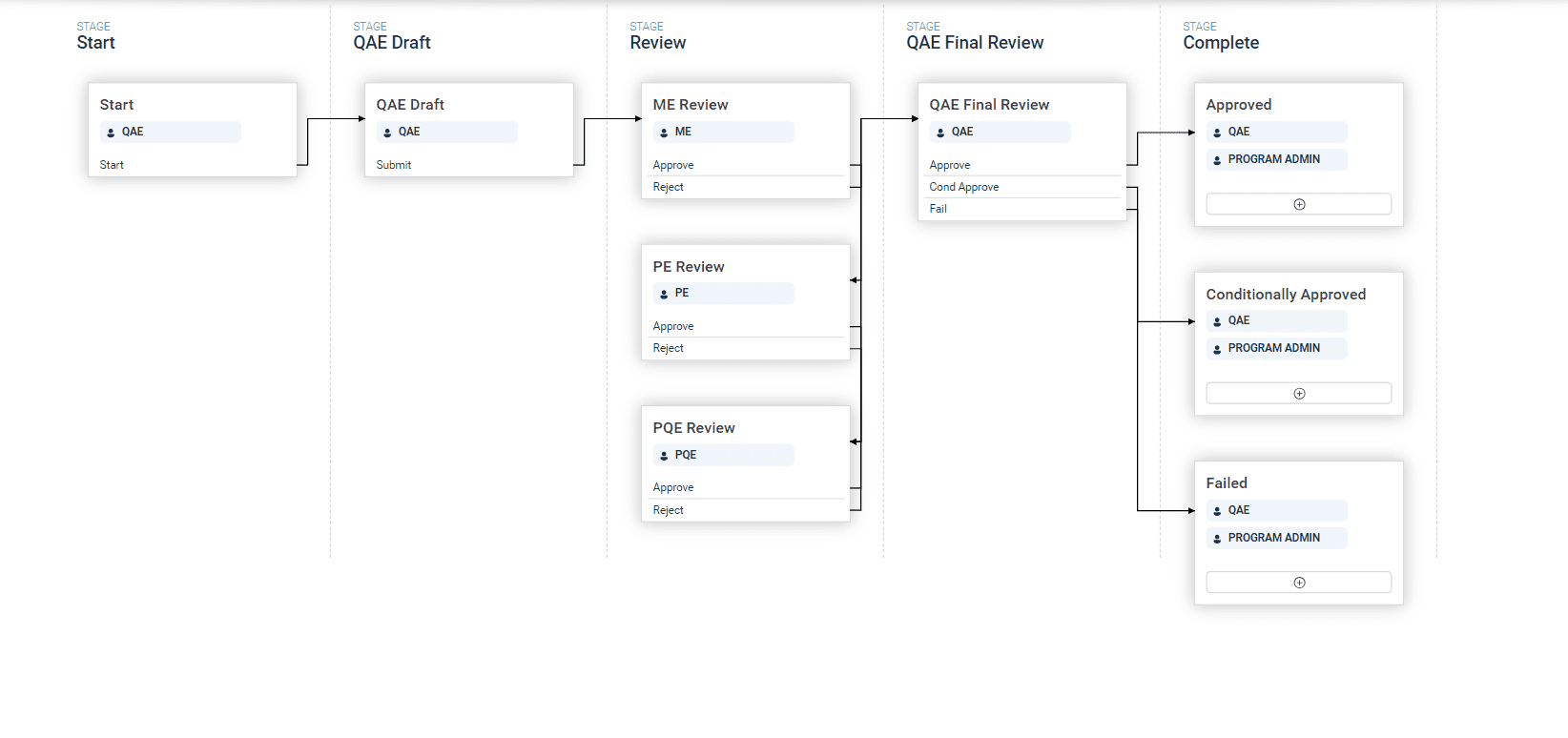

360 HUB leverages 360 CORE that is used by thousands of users worldwide every day to balloon parts, develop FAI, PPAP and more. Once the system is set up on your end, invite your suppliers to access your quality requirements from one source, and receive production data and inspection documents directly to you.