In recent years, more and more design and manufacturing companies are embracing solid and surface modeling techniques. However, 3D models often lack GD&T (geometric dimensioning and tolerancing) information that is necessary for the quality assurance organization.

The main problem with the typical CAD model is that it requires a separate drawing sheet to determine datum structure, key characteristics, and tolerancing to create an inspection plan. With 3D MBD, all pertinent product information and inspection planning data is included in one model, there is no longer a need for a 2D drawing.

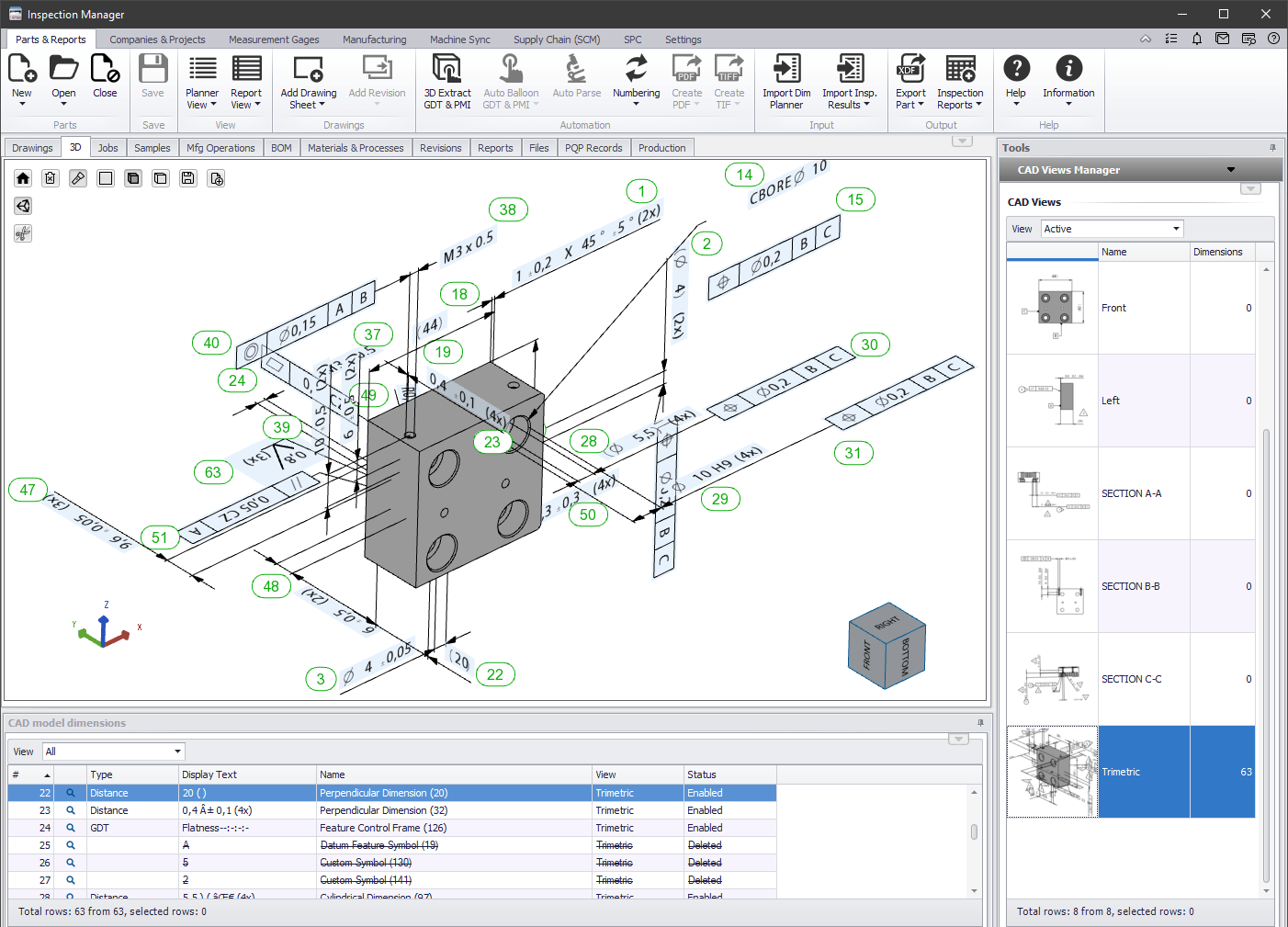

360 CORE enables you to use 3D MBD files directly into an automated, streamlined manufacturing quality process – just like using a 2D drawing.