Your one-stop shop for managing manufacturing quality. From 2D/3D MBD ballooning and inspection plans to FAI, SPC, PPAP, and more, we have the tools you need.

Manufacturing Quality Software.

Simplify. Digitize. Collaborate.

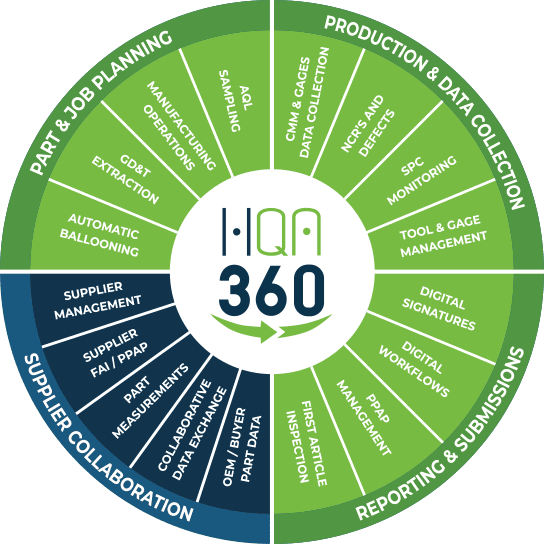

Our Platform

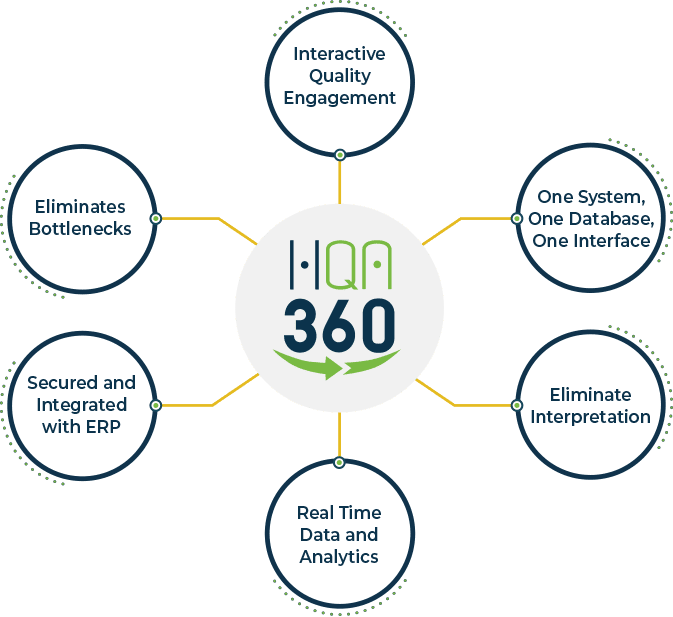

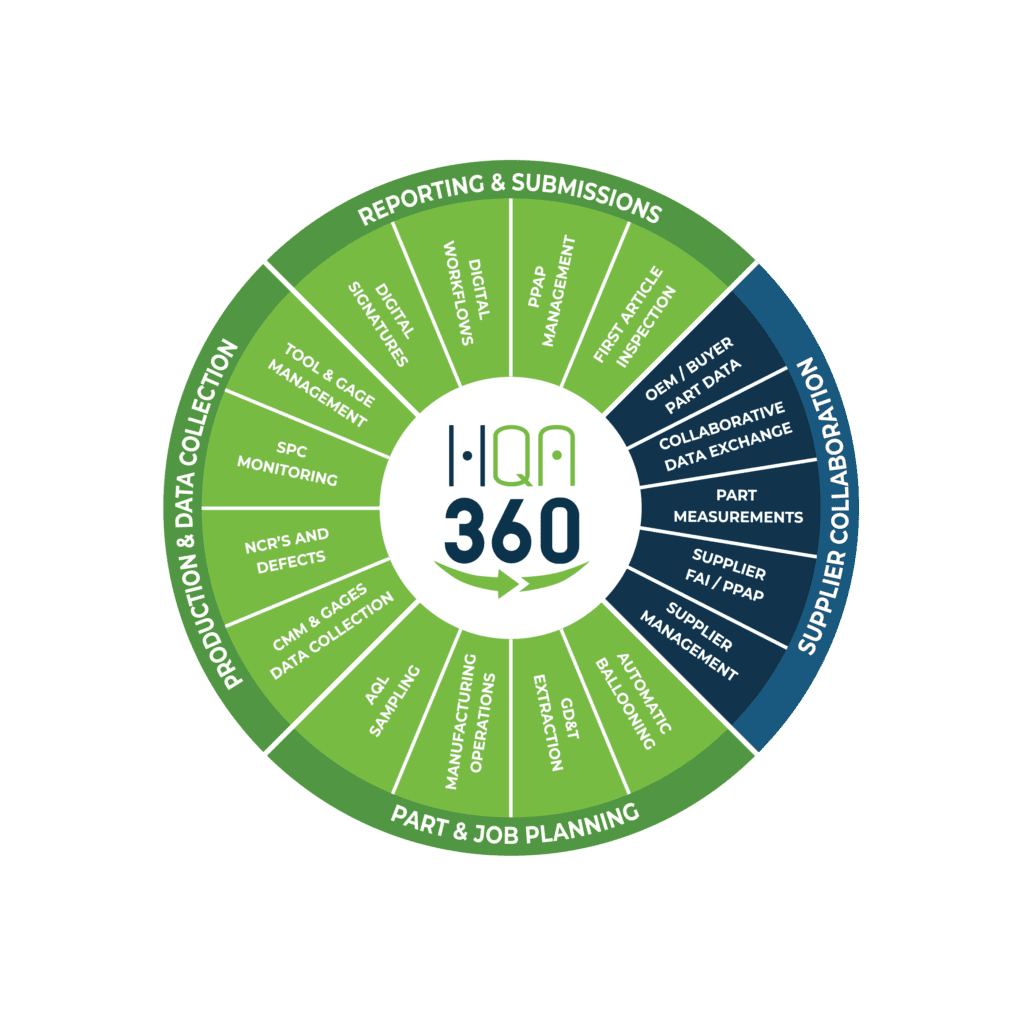

HQA 360 is our dynamic, integrated solution for manufacturing quality management, driving toward zero defects and saving 75% or more time in the process. Our modular platform allows us to offer packages adapted to customer’s needs, from small to large. Here are our key platform promises:

Interactive Quality Engagement

Automate collaboration with your suppliers, receive documentation, and eliminate incoming inspections

One System, One Database, One Interface

Have all your manufacturing quality data available in real time

Eliminate Interpretation

Automate in one click, 2D & 3D ballooning from PMIs to GD&T extraction to inspection

Real Time Data and Analytics

Avoid scrapping parts and lots with real-time manufacturing quality alerts during production

Secured and integrated with ERP

Seamless integration with all 3rd party software using High QA off-the-shelf connectors and RESTful API

Eliminates Bottlenecks

Your parts and products will be delivered on time, on budget, and to spec

Our Products

Join thousands of global manufacturers enhancing their quality processes with High QA’s versatile product suite. Experience automated ballooning, faster FAI’s & PPAP submissions, and seamless supplier communication for improved accuracy, efficiency, and bottom-line results.

The Authority:

360 CORE: A Comprehensive Manufacturing Quality Management Solution

360 CORE is an all-in-one, robust quality management solution designed for manufacturers to streamline and automate their quality processes. Whether working with 2D prints or 3D models, 360 CORE automates ballooning, GD&T, and 3D Model-Based Definition (3DMBD) with PMI extraction, seamlessly generating a Bill of Characteristics (BOC) and a true universal feature ID.

The platform enables you to assign and manage all quality requirements, from in-process inspections, SPC, and sampling to tool and gage management and PPAP documentation. Inspection data from any tool—whether a CMM or manual equipment—is automatically imported into 360 CORE, allowing for real-time reporting, including FAI and PPAP submissions, along with automated analysis and alerts to support preventive actions.

Built on a secure web platform architecture powered by years of industry expertise, 360 CORE fosters internal collaboration by allowing administrators to assign access levels, ensuring the right users see the right information at the right time. Available both in the Cloud and on-premises, 360 CORE offers flexible deployment options to meet your organization’s unique needs.

The Breakthrough:

360 HUB: Seamlessly Managing Your Supply Chain with Real-Time Collaboration

360 HUB is an advanced add-on solution to 360 CORE, designed to optimize and manage your supply chain by meeting all manufacturing quality requirements, interactively, close to real real-time. With 360 HUB, your suppliers can deliver parts on time, on budget, and on spec, without the need for complex interpretation or preparation—whether working with 2D prints or native 3D models.

You maintain full control over which data your suppliers can access while ensuring clear communication of requirements. Suppliers can submit all required data in real-time, using your templates and formats, streamlining processes like FAI, Real-Time SPC, and PPAP submissions. This reduces the need for on-site supplier visits and can even eliminate income inspection, saving time and resources.

Built on a highly secure web platform and backed by years of industry expertise, 360 HUB enables encrypted end-to-end collaboration across your supply chain. 360 HUB is available on the Cloud and on-premises (private Cloud), allowing you to choose the solution that best fits your organization’s needs while ensuring seamless and secure collaboration.

Key Features & Benefits to master manufacturing and supply chain quality.

The HQA 360 platform provides powerful and reliable manufacturing quality features and capabilities to gain better control of every manufacturing quality process and supply chain management.

Part Design Requirements

Automatic Ballooning of 2D & 3D Drawings

Material & Process Planning

Dynamic Workflow & Documents

Quality Planning

Detailed Inspections

In-Process Creation of Customer Dimensions

Definition of Critical Features, Inspection Methods, and Sample Plans

Documents

PPAP

PFMAE

Gage R&R

More…

Reports

P-FLow

SPC Performance

NCR

Lot Inspection

More…

Data Collection

Interactive

Automated Importing

Real-Time Dashboards

Supplier Collaboration

Data Exchange

Digital Inspection

Performance Tracking/Scoring

Customer Testimonials

Win More Contracts

I am winning more aerospace contracts because I can get my FAIRs out faster and cleaner than my competition.

S. Hunt

Operations / Quality Director

Jet Machined Products

72% Savings

By installing High QA software, we have a 72% average savings on quality planning and reporting processes.

A. Sufian

Project Engineer

Beverston Engineering

Save Time

High QA saves copious amounts of time. It’s ridiculously helpful. I’m not sure how anyone gets by without it.

T. Rousseau

Founder and Owner

Above All CNC

Faster FAI

High QA has been a game-changer for us. We have moved from completing 5-10 FAI reports a month to 5-10 a day.

P. Nelson

Engineering & Quality Manager

Louis Industries

Customer Stories

High QA software provides JD Machine with scalable growth while maintaining cost, quality, and delivery

JD Machine needed to keep overhead low and spend less time checking parts and more time making sure parts are efficiently run with high quality.

The search began for a system that could manage their manual inspection data collection as well as meet requirements of customer contracts, PPAP documentation, SPC, internal inspections, etc.

Their search ended with High QA software. It was the only solution that allowed JD Machine to scale from small beginnings to big growth and accommodate highly complex projects all while ensuring a high level of quality.