Manufacturing quality document and report generation, collaboration and management

for FAI, PPAP, AS9100, AS9102, AS13100, IATF 16949 and ISO 13485 standards

Create, Control and Collaborate on Quality Documents

with 360 CORE

High QA Production Quality Planning (PQP)

Don’t Let Quality Documents Manage You,

You Can Manage Them

Experience enhanced document efficiency and streamlined collaboration with High QA PQP (Production Quality Planning), the groundbreaking manufacturing quality document system.

Designed to advance quality report generation and collaboration among manufacturing facilities and suppliers, PQP revolutionizes the way quality documents are handled.

Fulfill documents needs for FAI, APQP and PPAP process requirements and generate quality documents for aerospace (AS9100, AS13100), automotive (IATF 16949), medical (ISO 13485), and other industry standards.

Access Your Quality Documents - Anytime, Any Place

Anything paper can do; electronic documents can do better.

Reduce costs and restrictions imposed by filing cabinets and paper documents. Adopt a paperless quality process that allows for convenient access to digital records stored in a central database, anytime, anywhere.

Embrace enhanced collaboration and customer interaction, revolutionize workflows, reduce waste, and unlock efficiencies with High QA PQP, the innovative manufacturing quality document system.

Save up to 70%

of the time spent managing documents

Enhance collaboration

between manufacturing and suppliers

Boost efficiency

in quality and manufacturing processes

Facilitate compliance

with industry standards

Meet expectations

and requirements of your customers

Bring Order to Chaos

Each customer wants a certain set of reports done in a certain way. With High QA PQP, templates and workflows are established for each individual customer.

With all the documents and reports stored in one central database, there is no need to remember and recall which documents are needed for each customer.

Dynamic Documents

Quality documents are “living documents” within the High QA central database. Editable fields are automatically populated from information within the database.

Eliminate Paper Documents

Digital documents and reports enable everyone to utilize the same information from the same source. It ensures consistency while reducing printing and storage costs of paper documents.

Process Status

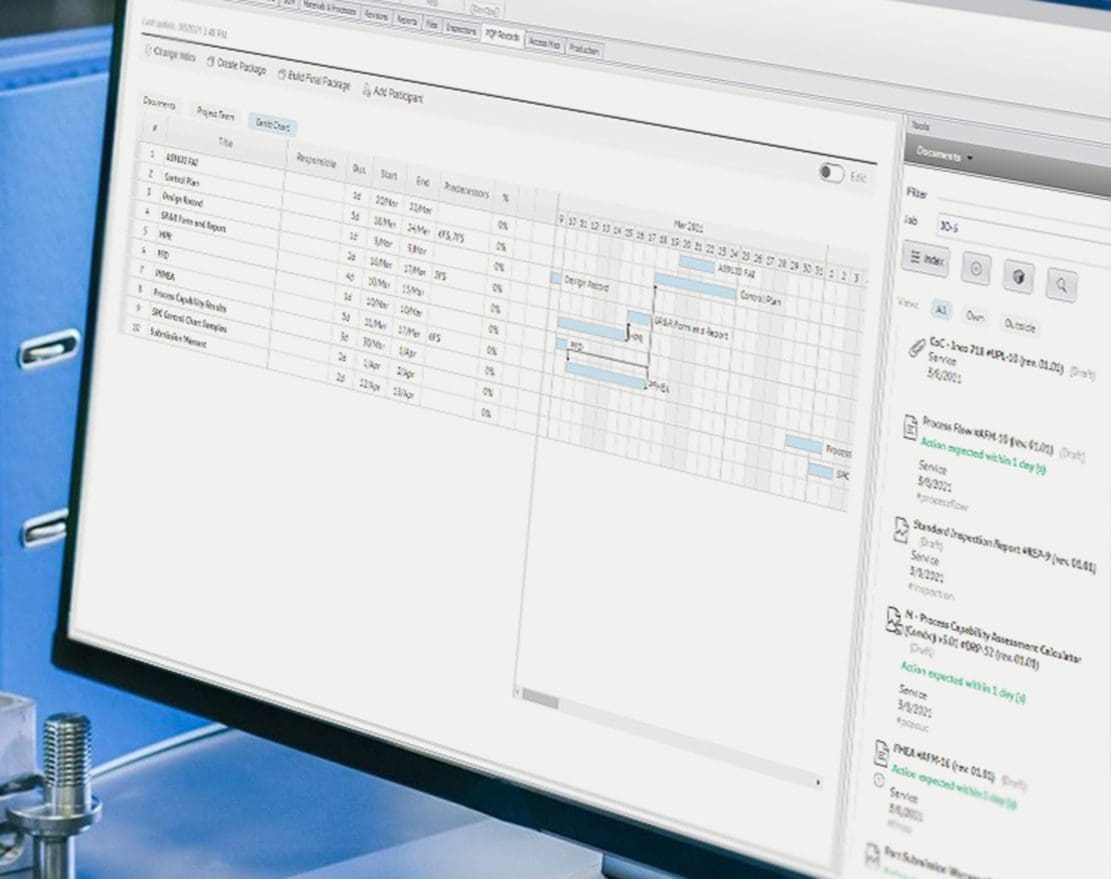

Monitor documents progress, pinpoint bottlenecks, and stay informed on submission package status. Know when a document is on schedule, falling behind or not completed. Maximize efficiency with real-time updates and Gantt charts.

Accountability

All permissions are controlled and defined by user responsibility. Easily determine who did what, when it was done and who approved it.

Traceability

No more digging through reams of paper or filing cabinets to see if a signature was obtained. Documents are approved and signed with digital signatures and stored in a central database.

Consistency

Ensure consistency in forms, workflows, and documentation across all jobs and customers. Choose from provided standard templates or customize templates according to individual preferences and needs.

One-Click Submission Package

Stop wasting time manually conforming to all the elements of the Production Part Approval Process (PPAP) in MS Excel and disparate systems. High QA PQP is a single software that streamlines and simplifies creating, managing and submitting your documents, including:

- Ballooned Drawings

- Inspection Plans

- Process Failure Mode Effects Analysis (PFMEA)

- Process Flow (PFlow) Diagrams

- Control Plans

- First Article Inspections (FAI)

- Non-Conformance Report (NCR)

- Statistical Process Control (SPC)

- Gage Management

- Material Certificates

- Part Submission Warrant (PSW)

How Do You Manage Your Manufacturing Quality Documents?

The OLD Way

Cumbersome, Excel-Based, Manual

Managing the internal manufacturing quality process is becoming increasingly more complex. Outsourcing parts to a supply chain increases the level of complexity with:

- Intensive labor and time to create each new quality project

- Multiple Excel spreadsheets with multiple columns, rows and tabs

- Delays from paper-based communications

- Errors from cutting and pasting critical data from multiple locations

- Variety of methods to control updates, revision control and engineering changes

- Lack of traceability by using paper-based spreadsheets, forms and documents

- Increased risk for material loss, rejected parts and delivery delays

- Missing documents, higher costs and lower part quality

The NEW Way

Automated, Non-Excel-Based, Dynamic

High QA Production Quality Planning (High QA PQP) is a powerful manufacturing Quality Management Solution (QMS) to fulfill APQP and PPAP process requirements with:

- Customized library of templates and forms

- Secure collaboration and communication

- Traceability and accountability for the entire quality process

- Streamlined PPAP process and other quality requirements using 2D drawings or 3D models.

- Compliance to AS9100, AS13100, IATF 16949, ISO 13485 and other quality standards and regulations in aerospace, automotive, medical, energy and other manufacturing industries

- An automated, paperless, database-driven solution that doesn’t rely on Microsoft Excel

Essential Productivity Tools and Features

Centralized database for documents and forms

Adaptable project management templates

Comprehensive automated forms

Secure user access control

Standards-driven production processes

Supplier performance evaluation

Electronic signature confirmations

Powerful revision control management

Flexible configurations and business workflows

High QA 360 Exchange Server for remote and in-network collaboration

Streamlined practices for compliance with manufacturing quality standards

Customizable library of templates for each buyer and OEM

Powerful Project Management

for All Your Quality and Manufacturing Needs

Uniting People, Projects and Processes for Unparalleled Manufacturing Quality

High QA PQP revolutionizes the way product submission packages are composed, generated, tracked, signed, and stored.

One integrated software solution combines print ballooning, inspection plan composition, gage management, data collection, NCR tracking, statistical analysis (SPC) and FAI’s with 1-click, along with automatic, seamless generation for your PFMEA, Control Plan, Process Flow Diagram (PFlow), Part Submission Warrant (PSW), SPC Control Chart, and Gage R&R documents.

High QA delivers a refreshing and simplified approach to delivering complete submission packages for AS13100, ISO13485, or any other industry standard, instead of only managing documents. Let your data work for you!

Align and Unify Suppliers and Buyers

High QA PQP enables cross-functional teams to seamlessly and securely collaborate and communicate on manufacturing documents and processes. It also accelerates the time-to-ship parts and reduces scrap by: