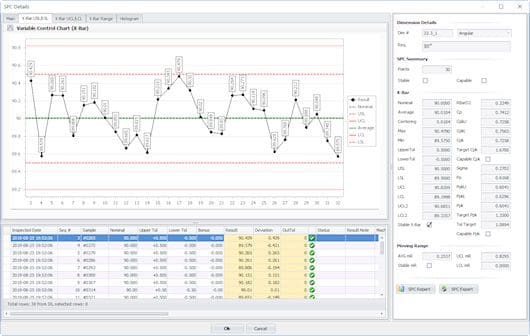

With the Statistical Process Control (SPC) solution from High QA, collect data in a centralized database to analyze real-time run charts, X-bar and R, stability (Cp, Pp) and capability (Cpk, Ppk) information to improve process performance, manufacturing quality and part consistency.

Improve Statistical Process Control and Quality

with 360 CORE

Real-Time Statistical Process Control (SPC)

Harness the power of your data to monitor, control and improve your quality process through statistical analysis.

Does your data benefit you?

Do you know where it is?

Is it useful?

”I have reams and reams of data ... but no useful information

High QA Prospect

Monitor and Manage Operational Quality

Monitor and Manage Operational Quality

Caliper? Micrometer? Vision? CMM? CNC Probe? Track ALL your data in one centralized database providing real-time tracking of product and process quality with instant Cp, Cpk, Pp, and Ppk readings.

Predict and Prevent Critical Quality Issues

Predict and Prevent Critical Quality Issues

Real-time SPC collects product and process data as it happens. High QA’s shop floor tools display calculated control limits, specification limits, Cp, Cpk, Pp and Ppk values on an easy-to-read display screen and are instantly updated when the data is entered. Turn a reactive process into proactive instantly!

Improve Efficiency and Productivity

Improve Efficiency and Productivity

High QA provides insights into the stability and capability of your manufacturing processes. You will have the ability to compare data from machines, gages, lots, samples, even facilities! This will provide insights to your processes that can be applied to process improvement, reduced scrap rates, and more accurate quoting!

See how High QA can harness the power of your SPC data. REQUEST A DEMO

Capture, Track, Analyze and Report Quality While Manufacturing Parts with Comprehensive SPC Capabilities

Statistical Process Control (SPC) in 360 CORE provides the collection, analysis, visualization and workflow capabilities of manufacturing operations data. Manufacturing processes are improved through statistical analysis. The result of SPC is improved product quality and uniformity, reduced scrap and rework costs, reduced process variation and reduced material consumption.

See how High QA you can collect, analyze and report SPC data. REQUEST A DEMO

Collect

From intuitive shop-floor interfaces to enter manually measured features (attribute gage, thread gage, etc.) to automatically importing the data from an automated measurement system (CMM, Arm, Tracker, Vision, CNC Probe, etc.), High QA stores it all in one, centralized location providing you with a single-source of truth.

Analyze

Monitor and analyze data as it’s being measured on the shop floor and have instantly-updated control charts, with Cp, Cpk, Pp, and Ppk values.

A more extensive, yet still real-time, SPC toolset is available in the core High QA package including analysis of Max, Min, Mean, UCL, LCL, RBar, Cp, Cpk, CpkU, CpkL, Sigma, Pp, PpkU, PpkL, Ppk, and Average moving range (mR). This, combined with single-click X-bar and R charts (mean and range), provides users with data needed for submission packages and insights into process improvement.

Alert

In today’s manufacturing environment, being notified after-the-fact is too late. High QA provides alerts for a multitude of parameters such as NCR’s, Out of Tolerance, Job Complete, Gage Expired, and a host of others! Too much? Combine the notifications into a report that is sent at a determined frequency. The choice is yours – we provide the tools, you provide the details!

Report

360 CORE makes it easy to select, filter and graph data for simple and clear visualization – on your schedule. Whether you need Cpk reports daily or NCR reports weekly, with just a few clicks it’s set up and running.

Easily set up customized SPC reports once with Pp and Ppk for your boss or customer. Out-of-tolerance reports for completed jobs are easily generated with 360 CORE.

”With High QA software, we have been able to improve our manufacturing procedures. We have an average savings of 72% on quality planning and reporting processes.

Amr Sufian, Project Engineer, Beverston Engineering

Learn More about Statistical Process Control (SPC)

What is Statistical Process Control (SPC)?

Statistical Process Control (SPC) is an industry-standard methodology for measuring and controlling quality during the manufacturing process. Quality data and process measurements are obtained in real-time during manufacturing. The data is plotted on a graph with pre-determined control limits. Control limits are determined by the capability of the process or by the client’s needs.

Data that falls within the control limits indicates that everything is operating as expected. Any variation within the control limits is likely due to a natural variation that is expected as part of the process. Data that falls outside of the control limits indicates something within the process should be changed to correct the issue before defects occur.

The importance of statistical control is to show what the process can produce over time. Statistical process control allows predictions to be made about how a process will run in the future based on how it ran in the past. This helps determine if the process can produce output to meet specifications.

What is real-time Statistical Process Control (SPC)?

Real-time SPC is the use of SPC charts and analysis during the time of production for immediate process feedback. Supply chain and manufacturing processes depend on a combination of machinery and automation technology to produce products more accurately and more efficiently. Real-time SPC software allow operations to continuously improve quality control within manufacturing processes.

Real-time SPC software can significantly enhance manufacturing quality initiatives. When manufacturing capacity increases, quality management software is needed to provide visibility into manufacturing quality throughout the supply chain to help decrease risks, part recalls and overall costs.

Real-time SPC software processes data in real time as it is collected. This provides operators with tools to prevent and catch defects before they leave the manufacturing floor. Real-time SPC software allows manufacturers to understand which processes are statistically out of control.

What is Statistical Process Control (SPC) Software?

Statistical process control (SPC) software provides an ongoing statistical analysis by collecting data in real-time and alerting the manufacturer to any results that fall outside the accepted range. This, in turn, helps reduce process variation, improves manufacturing efficiency and lowers overall production costs.

SPC software provides capabilities that monitor and analyze data in real-time to reduce variation in a production process or other system. It also helps to identify the origin of a problem and demonstrate whether or not an improvement is effective.

Using statistical methods to provide insight and accuracy into manufacturing processes allows manufacturers to keep operations running, meet customer requirements, minimize waste, maximize profits, and ensure quality.

The High QA Difference

OUR SOFTWARE

High QA unites engineering, production and inspection teams internally and throughout the supply chain with an integrated solution to plan, manage, document and control manufacturing quality from ballooning and planning to production, reporting and submissions.

OUR PEOPLE

We don’t just have brainpower in manufacturing quality software, we have people with heart, grit and a ton of understanding. We live and breathe quality. It is in our software and in our people. You might say we are the quality experts.

YOUR SUCCESS

Working together, we can digitally transform your manufacturing quality processes. And that leads to improved quality products, increased customer satisfaction and a successful business.

High QA is Your All-in-One, Get-It-Done Software for Manufacturing Quality

Reduce costs, improve quality, streamline processes, and maintain compliance internally and across your entire supply chain

Ballooning / Bubbling

One-Click to Balloon Drawings and 3D Models, Extract GD&T and PMI Data and Create Inspection Plans

First Article Inspection (FAI)

Powerful FAI Generation, Management and Reporting for Quality and Manufacturing

PPAP Requirements

The Most Complete Non-Excel-Based Manufacturing Quality Project Management Software Solution